Printing plays a more crucial role in the Food and Beverage industry than most people think. For a variety of reasons, the food and beverage industry requires specialised labelling. Labels are essential in disseminating product information about the product. Meanwhile, the overall packaging is important to make a good first impression on your customers.

Why print is more important in the food and beverage business

Printing for food and beverage businesses is more than just industry and safety compliance. It’s the first point of interaction between a potential customer and your goods. It’s a crucial element in marketing your product.

RECOMMENDED: How can Printing Helps Local Government and Politicians

Compliance

Printing is also part of compliance with the labelling regulations of the Food Standards Australia New Zealand (FSANZ). According to their definition of “labelling” in the food and beverage business, it is “all labels and other written, printed, or graphic matters upon any article or any of its containers or wrappers”.

Quick fact

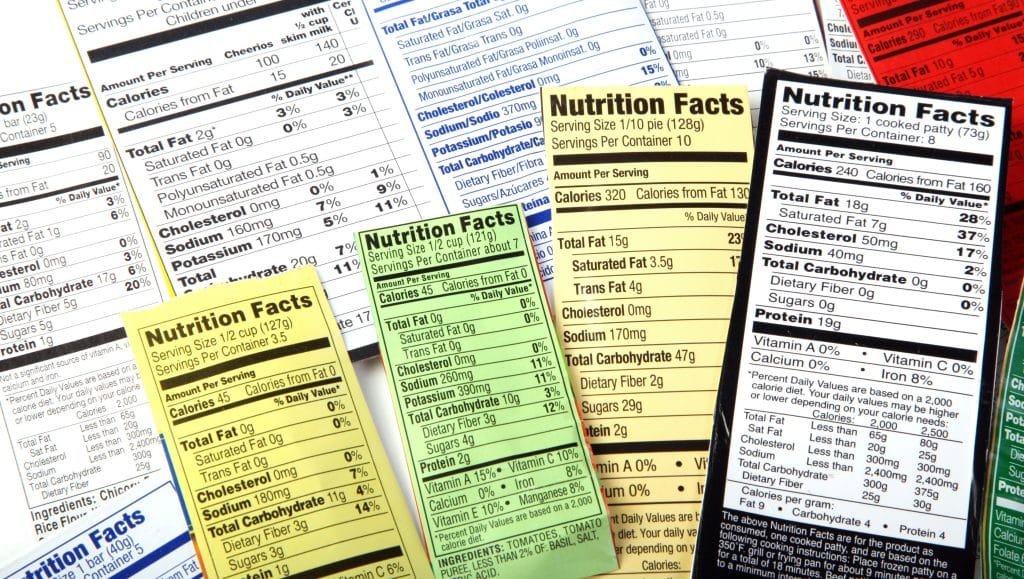

Commercially sold products other than fresh produce are required to have an important breakdown of their nutritional content through the use of labels. These labels must be displayed on the packaging for the consumer’s information. For a food and beverage manufacturer to ensure that the consumers are informed of the ingredients of the food they’re consuming.

RECOMMENDED: For Design Tips for Creating your Own Business Cards

Branding

Your packaging and its prints are a critical element of branding. The design, colour, and all the elements that come with the packaging of your food and beverage products are what give it identity and become recognizable to customers. The quality of your print will also reflect the quality of your product, thus, it’s also crucial to ensure that the print is in its best form possible.

Food packaging labels are an investment in your brand and goods. The correct label increases sales, consumer recognition, and provides a measurable return on investment. To achieve these objectives, your label must:

- Draw attention to your goods and make them stand out on store shelves.

- Customers should understand the value of your product.

- Create a recognisable and trustworthy brand.

- All FSANZ-required information should be communicated.

Print essentials to consider for food and beverage use

As simple as printing may seem, it’s a different case for food and beverage products. The prints will be on different mediums, not just paper. Some food containers are plastic, while some are glass, not to mention their dimension and shape can play a factor in how to execute a print properly.

RECOMMENDED: Five Ways to Beat Digital Fatigue

Refrigeration proof

Adhesives must be compatible with the manufacturing and storage environments to guarantee proper application. At room temperature, a label with a freezer-style adhesive may become detached, just as a room-temperature adhesive may become unadhered in a cool or cold environment. When kept at ambient temperature or frozen, an adhesive meant for refrigerated settings will not adhere well.

RECOMMENDED: How Prints remain Significant in the Age of Digital Events

Backings

The material from which labels are peeled is a crucial consideration that is sometimes overlooked. Not all materials are suitable under specific conditions or environments, and machines that apply these labels require a different configuration than applying it by hand. Standard, lightweight paper packaging, for example, is adequate for dry, by-hand, room-temperature application but will fail in a moist environment if the labels are applied using a high-speed application machine.

Product and container shape

In the food and beverage business, while most labels are put to smooth, flat surfaces, this is not always the case. Many products, most notably meat and cheese cuts, are vacuum packed and have a wide range of application surfaces. On the uneven surfaces presented by natural food products, the stiff label substrate and brittle adhesive that work well on flat cardboard packaging will operate badly. Conformable substrates and aggressive, flexible adhesives, on the other hand, are essential.

RECOMMENDED: How can Print Improve your Events

Safety standard

Unlike regular printing purposes, materials used for prints in the F&B industry have a different set of guidelines upholding health and safety regulations. FSANZ requires that they should be safe and hazard-free as they serve as the initial point of contact between your product and the customers. Standard pressure-sensitive paper labels are the most popular, followed by changeable information paper labels, white films, specialty papers, various synthetic materials, and a range of adhesives.

These materials can’t be bought from retail stores, thus they require specialized printing materials from paper, adhesives, to ink.

Adding value to your food and beverage product

Print companies specialising in food and beverage printing have a variety of specialized labels. Sure, the FSANZ demands particular information and layout standards from a label but labels have a lot to offer other than compliance and branding. Different label types thrive in different areas, therefore food producers should think about what they really want from their food packaging label.

Is it critical that the label be long-lasting and sticky so that the food item’s label is never lost or too faded to read? Is there a lot of information that has to be conveyed on the label? Should your label provide a consumer with another incentive, such as a coupon or a rebate?

Depending on your goal and your food product, you can add value to it by using the following labels.

- Flexible packaging

- Pressure-sensitive labels

- Cut-and-stack labels

- Extended content labels

- Traditional rigid packaging

- Shrink sleeves

- Instantly redeemable coupon (IRC) labels

This arduous list of challenges hardly touches the surface of the special considerations that must be made when designing food and beverage labels. It doesn’t even take into account highly specialised labels like collectible lift-off wine labels, FSANZ and other government labelling laws, the suitability of digital printing, and a plethora of other factors.